Welded Heavy Duty Grating

Welded Heavy Duty Gratings are designed to service applications subject to heavy rolling and static loads such as highways, plant floors, loading docks, inlet covers, and airports. Since conditions can range from smaller forklift to large truck or aircraft traffic, heavy duty gratings are manufactured in a wide range of bar sizes and spacings.

Design Criteria

Vehicular loads are designed in conformance with current AASHTO specifications for classifications H-15 through H-25. Automobile and forklift loads are similarly evaluated with loads calculated and distributed in accordance with the "Maximum Traffic Conditions" presented below.

If your application is not adequately addressed by these load conditions, please contact us and we will gladly assist in the selection of an appropriate heavy duty grating for your specific need.

Materials & Spacings

Heavy duty gratings are manufactured in carbon steel and 300 series stainless steels. Carbon steel products are available bare (no finish), painted with manufacturers standard paint, or hot dip galvanized. Stainless steel products are available mill finish, commercially cleaned, or electro-polished. Below you will find a table of spacings for our most popular products.

Table of Spacings

Heavy Duty Grating Selection

Bearing Bar Selection

Once the bar spacing is selected, the bearing bar size must be specified based upon the load and unsupported clear span to be served. The load tables provide the maximum clear span for our most popular products based on the traffic conditions defined on this page. These tables incorporate strict limitations where design deflection shall not exceed the lesser of L/400 or .125" for the spans indicated.

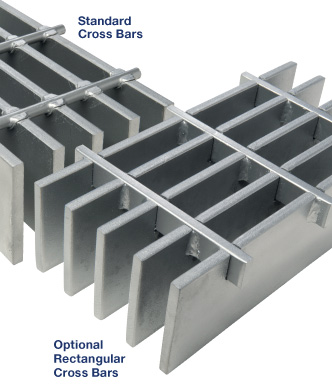

Cross Bar Selection

While bearing bar selection is critical for specifying a proper heavy duty grating, the life cycle of your installation will often be influenced by the selection of the appropriate cross bar. The table below details the variety of cross bar sizes available.

The cross bars listed for Standard Loads are the customary twisted square or round cross bars supplied by Grating Pacific for a particular bearing bar size and spacing. These sizes have been selected to maximize manufacturing efficiency and are best used when the grating is subject to intermittent traffic with occasional full capacity loading.

The cross bars listed for Severe Loads are optional and will provide superior durability when gratings are subject to intense, continuous, or repetitious traffic. Ideal for trench covers, highways, and inlet grates, these cross bars enhance lateral stiffness thereby extending the service life of the grating. When specifying gratings with bearing bars centered at 1-3/8", 1-7/8", or 2-3/8" on center, consideration of Severe Loading cross bars is highly recommended.

Note: In the event that a cross bar size is not specified, the cross bar shall be selected at the discretion of the manufacturer.

Banding

Heavy duty gratings are commonly subjected to shock and impact loads and it is highly recommended that all open ends be banded. The welded band bar helps distribute impact loads and minimizes distortion when subjected to repetitive traffic patterns.

Serrated Surface

Optional heavy duty serrated bearing bars enhance skid-resistance.

Consider this surface for applications subject to the accumulation of liquids or lubricants or inclined installations.

How to Specify Heavy Duty Bar Grating

- Select type of grating:

- "W" for welded steel

- "WS" for welded stainless steel

- Select bar spacing from load tables

- Select bearing bar size from load tables

-

Specify cross bar size from selection table above

-

Specify plain or serrated surface

-

Specify banding and any additional trim required

- Specify finish:

- Bare steel (no finish)

- Painted (red, black, silver, other)

- Hot dip galvanized (per ASTM A-123)

-

Other

- Specify fasteners (if required)